- +91 8055996347

- info@3dreality.in

- Chapru nagar square, CA road, Nagpur, Maharashtra-440008

The manufacturing world is undergoing a seismic shift, driven by the rise of 3D printing, also known as additive manufacturing. What was once considered a tool for prototyping has now become a powerful alternative to traditional manufacturing methods. From aerospace and automotive to healthcare and construction, 3D printing is transforming how we design, produce, and deliver products. Its influence stretches across cost reduction, product innovation, supply chain optimization, and sustainable practices, signaling a new era for production as we know it.

Traditional production methods like CNC machining, injection molding, and casting have powered industrial growth for decades. However, these processes come with certain limitations:

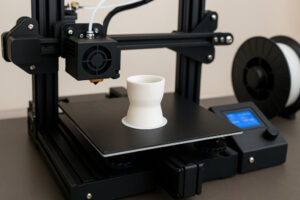

3D printing eliminates many of these barriers by building parts layer by layer from a digital model, often using materials like plastics, resins, metals, or composites. This makes it faster, more versatile, and more efficient.

One of the most significant advantages of 3D printing is the ability to produce functional prototypes quickly and cost-effectively. This allows designers and engineers to test, iterate, and finalize their products in a matter of days instead of weeks or months.

This shortened development cycle:

Unlike traditional production, which relies on mass production for cost-effectiveness, 3D printing thrives in low-volume and customized manufacturing. Each item can be tailored to specific user requirements without additional tooling or setup.

Applications include:

Traditional subtractive manufacturing cuts away material to shape a product, resulting in waste. In contrast, 3D printing uses only the material needed to build the item, significantly reducing waste and lowering material costs.

This is especially valuable in industries using expensive materials, such as aerospace-grade titanium or rare polymers.

3D printing enables on-demand production, which reduces reliance on long supply chains, large inventories, and overseas manufacturing. Companies can produce parts locally, closer to the end-user, reducing lead times, shipping costs, and environmental impact.

Healthcare

3D printing is revolutionizing the medical industry. Surgeons now use 3D-printed anatomical models for pre-operative planning, improving surgical accuracy. Custom implants, prosthetics, and dental solutions are created to fit individual patients perfectly, enhancing recovery and comfort.

Emerging technologies are exploring the bioprinting of tissues and organs, pushing the boundaries of what’s possible in regenerative medicine.

Aerospace and Defense

These industries benefit from 3D printing’s ability to create lightweight, strong, and complex parts. Components like fuel nozzles, brackets, and turbine blades are now being produced with reduced weight and improved performance.

The reduced weight translates to fuel savings and lower emissions, making aerospace applications a natural fit for additive manufacturing.

Automotive

Automotive companies are using 3D printing for rapid tooling, custom parts, and lightweight components. Concept models and functional prototypes can be tested within days, and even low-volume luxury vehicles now include 3D-printed interior and structural parts.

Construction

3D-printed buildings and structures are becoming more common. Using large-scale printers, companies are producing homes in a fraction of the time and cost compared to traditional construction. The potential to address housing shortages and disaster relief is immense.

The Economic and Environmental Impact

Cost Efficiency

While the initial investment in 3D printing equipment can be significant, the long-term cost savings from reduced tooling, labor, and materials are substantial. Small businesses can now enter the manufacturing space without needing massive capital investment.

Sustainability

By minimizing waste, reducing transportation emissions through local production, and enabling eco-friendly materials, 3D printing supports the shift toward sustainable manufacturing. Companies are also experimenting with recycled plastics and bio-based materials, further contributing to environmental goals.

Challenges to Overcome

Despite its many benefits, 3D printing is not without challenges:

However, as research and development continue to evolve, these hurdles are gradually being addressed, making 3D printing more viable for high-volume and mission-critical applications.

As demand increases, local providers of 3D printing are expanding rapidly. Cities like Nagpur are witnessing the emergence of specialized service providers offering affordable, high-quality 3D printing solutions for businesses and individuals alike.

If you’re looking for the best 3D printing services in Nagpur, you’ll find companies that deliver everything from prototype development and custom product manufacturing to educational and medical model printing, right at your doorstep.

3D printing is no longer the future—it is the present of manufacturing. With its ability to simplify processes, reduce waste, and foster innovation, it’s clear that additive manufacturing is transforming traditional production across every industry. As the technology becomes more accessible, it will redefine how products are imagined, created, and delivered on a global scale.

Click here to explore more informative and helpful blogs.