- +91 8055996347

- info@3dreality.in

- Chapru nagar square, CA road, Nagpur, Maharashtra-440008

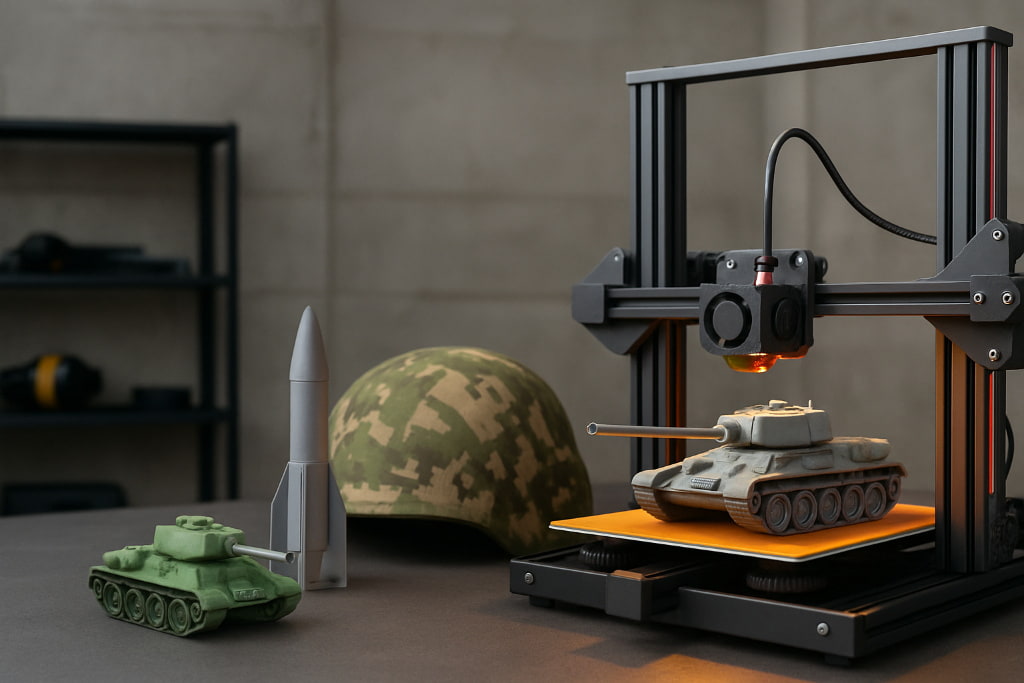

In the high-stakes world of defense and space exploration, speed, precision, and adaptability are non-negotiable. Enter 3D printing—also known as additive manufacturing—a technology that’s not just revolutionizing prototyping but is now reshaping how the military and aerospace industries design, build, and deploy critical equipment. What was once used to print plastic parts in labs is now crafting rocket engines, field-ready drones, and mission-critical military gear.

As of 2025, 3D printing is no longer a futuristic concept—it’s a battlefield asset and a launchpad enabler.

The aerospace sector was among the earliest adopters of 3D printing, and for good reason. Aircraft and spacecraft rely on lightweight, strong materials and custom components—exactly where additive manufacturing excels.

Key Innovations:

This evolution from prototyping to production means parts that once took months to machine can now be printed in days or even hours—a game-changer in competitive aerospace timelines.

From mobile field units to naval ships, military forces are embracing 3D printing to increase operational flexibility.

By decentralizing manufacturing, 3D printing helps militaries become more self-reliant, especially in remote or hostile environments.

Military and aerospace applications demand durability, precision, and heat resistance. The most used materials include:

Advanced printing techniques like Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM), and Binder Jetting make it possible to create parts with complex geometries that traditional machining cannot produce.

|

Benefit |

Impact |

|

Reduced lead times |

Parts can be produced in days, not weeks or months. |

|

Lower costs |

Minimizes waste and eliminates tooling costs. |

|

Customization |

Mission-specific parts can be tailored instantly. |

|

Portability |

Field printers allow on-site manufacturing in remote areas. |

| Supply chain resilience |

Reduced reliance on external vendors. |

Despite its promise, 3D printing still faces some hurdles in defense and aerospace:

But as AI and simulation tools improve, many of these issues are being solved in real-time.

Looking ahead, the future of 3D printing in military and aerospace includes:

What’s certain is that additive manufacturing is becoming strategically indispensable for both defense and space missions.

3D printing in military and aerospace isn’t just an innovation—it’s a strategic advantage. From enabling soldiers to print tools in combat zones to revolutionizing how we build rockets, this technology is setting new standards in speed, efficiency, and adaptability.

As the industry continues to evolve, those who adopt and master additive manufacturing will lead the next generation of defense and space exploration.