- +91 8055996347

- info@3dreality.in

- Chapru nagar square, CA road, Nagpur, Maharashtra-440008

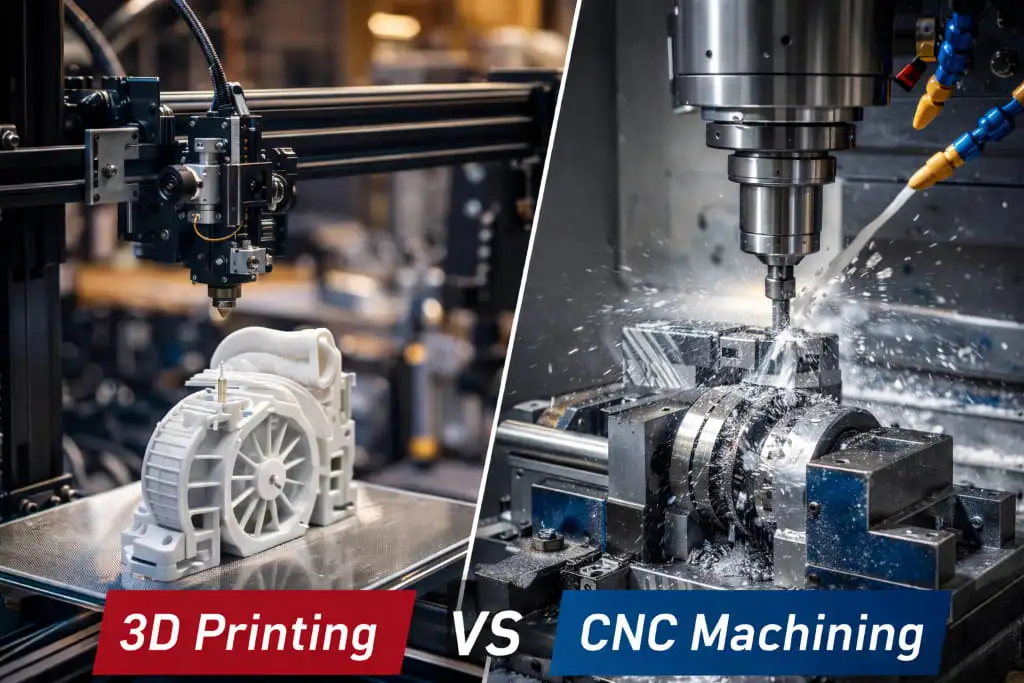

In today’s fast-evolving manufacturing world, two technologies dominate modern production methods: 3D printing and CNC machining. Both are widely used across industries like automotive, aerospace, medical, construction, and product design. But when it comes to choosing the right solution, one common question people search on Google is:

“3D printing vs CNC machining – which is better?”

The answer depends on your project needs, budget, material requirements, and production volume. In this article, we’ll compare 3D printing vs CNC machining in a clear, practical, and SEO-friendly way to help you make the right decision.

3D printing, also known as additive manufacturing, is a process where objects are created layer by layer from a digital 3D model. Materials such as plastic, resin, metal, or concrete are deposited precisely to form the final product.

Popular 3D printing technologies include:

Because of its flexibility and speed, 3D printing is widely searched for prototyping, custom manufacturing, and low-volume production.

CNC machining (Computer Numerical Control) is a subtractive manufacturing process. In this method, material is removed from a solid block using cutting tools like drills, mills, and lathes to achieve the desired shape.

CNC machining is known for:

It is commonly used for metal parts, industrial components, and high-volume manufacturing.

This makes 3D printing more material-efficient and eco-friendly.

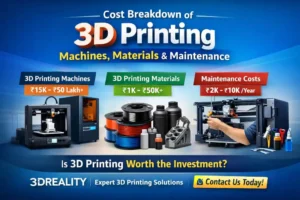

One of the most searched topics is 3D printing cost vs CNC machining cost.

For startups and innovators, 3D printing is often the better choice.

3D printing allows complex geometries, internal channels, and lightweight designs that are impossible or very costly with CNC machining.

CNC machining works best for:

If design freedom matters, 3D printing clearly wins.

This is why rapid prototyping with 3D printing is extremely popular on Google searches.

For heavy-duty industrial parts, CNC machining may still be preferred.

3D printing is the best choice when:

Industries using 3D printing include healthcare, construction, architecture, automotive prototyping, and consumer products.

CNC machining is ideal when:

It remains a backbone of traditional manufacturing.

The future isn’t about choosing one over the other—it’s about using both together. Many manufacturers now combine 3D printing and CNC machining for hybrid manufacturing. A part may be 3D printed first and then CNC-finished for accuracy.

As 3D printing technology advances, it is rapidly closing the gap in strength, material variety, and surface quality.

There is no single winner in 3D printing vs CNC machining. The better option depends on your goals:

3D printing is transforming how products are designed and manufactured, making it a powerful solution for modern industries.

If you are exploring advanced manufacturing solutions, 3DReality welcomes you — we are experts in the 3D printing industry. Contact us to discover how 3D printing can transform your ideas into reality.

Both 3D printing and CNC machining have unique strengths. Understanding their differences helps you choose the right technology, save costs, and improve product quality. As industries move toward smarter and faster production, 3D printing is no longer the future — it’s the present.